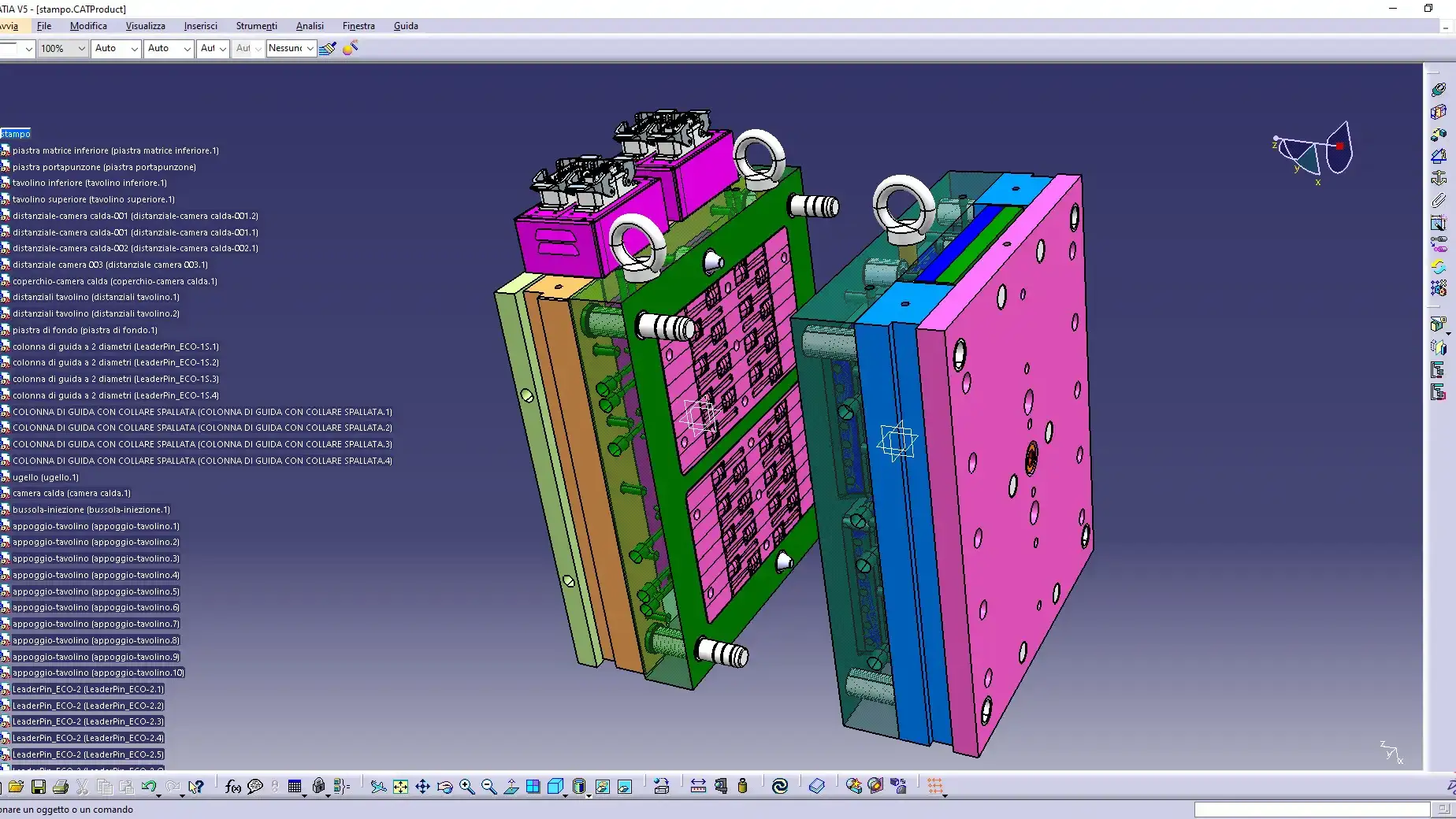

mould design and construction

Design and engineering of moulds for injection moulding of plastic products

01

needs analysis

and design

Each project starts with an analysis of the customer’s requirements and continues with a detailed study, supported by functional, aesthetic and mechanical evaluations through flow and deformation analysis.

Continuous interaction with the customer allows each design aspect to be precisely defined up to complete industrialisation.

02

prototyping and

functional verification

Using 3D printing technologies, we produce physical prototypes in different materials, which are useful for validating design solutions and optimising geometry and performance before the final mould is built.

This phase allows a concrete evaluation of the component in terms of form, assembly and functionality.

03

mould

making

Mould making is entrusted to highly qualified machine shops, selected according to the complexity of the project and the agreed technical-economic objectives. In this way, we guarantee maximum consistency between the quality of the result, delivery time and the required investment.